Digital Production Management for Warehouse-Driven Businesses

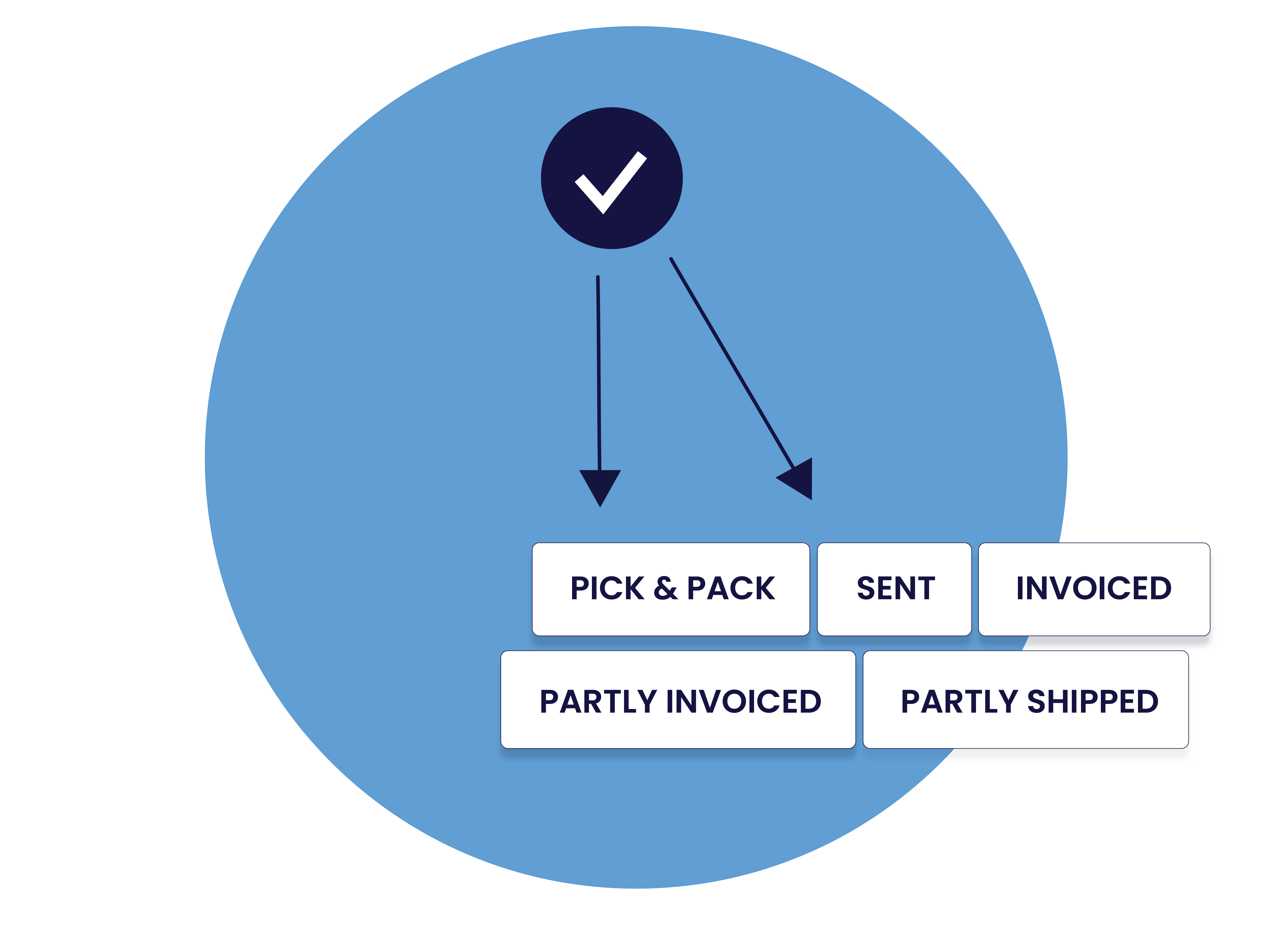

If your company manufactures finished goods, you need to tie your shoes tightly and keep a cool head from the ordering of raw materials to sending off the sales order. Your production can encounter many bumps along the way. Without solid streamlining between purchases, inventory management, the assembly of raw materials, and the execution of production orders, you will face production halts and delivery delays. Therefore, effective production management is crucial for your business.

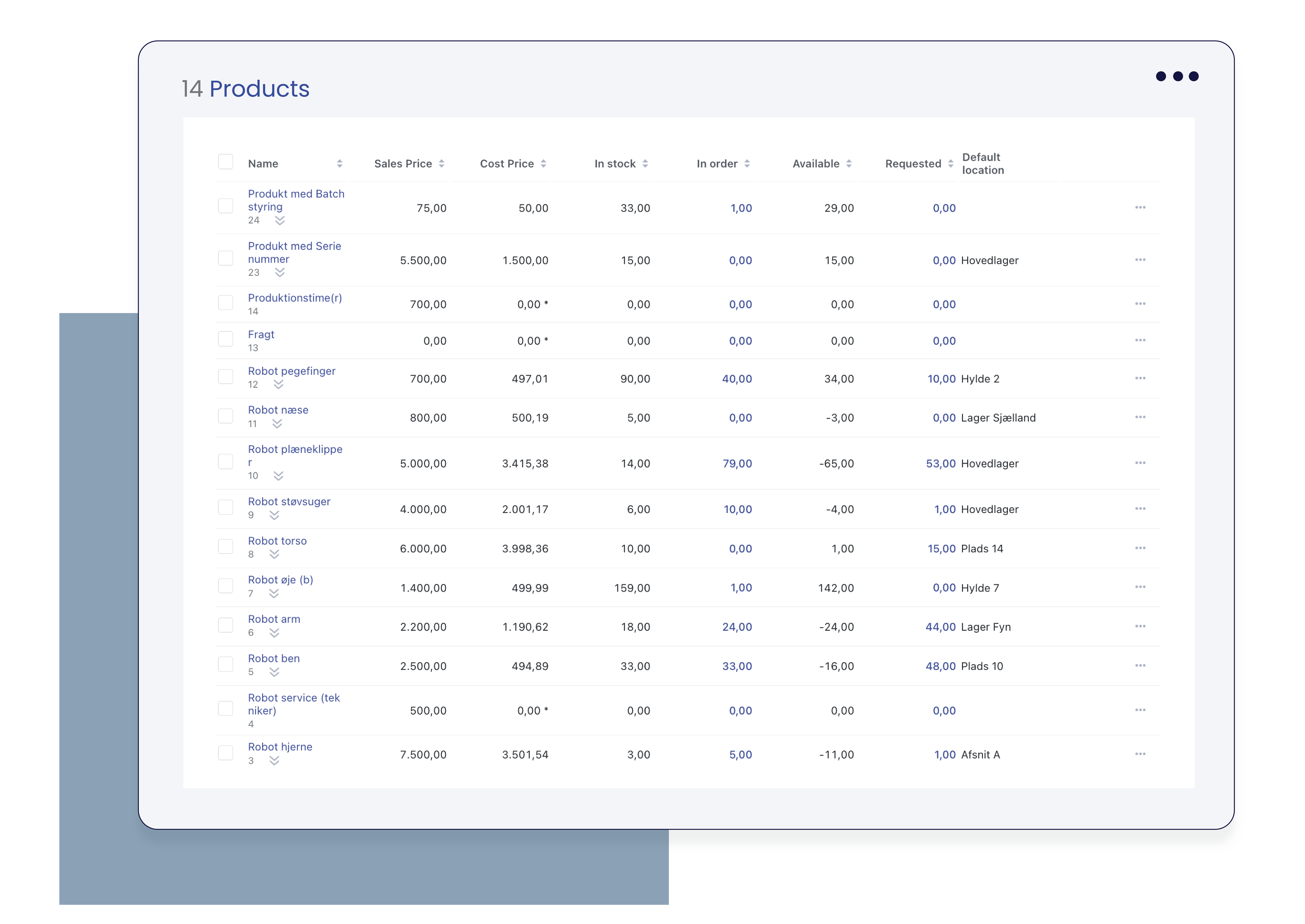

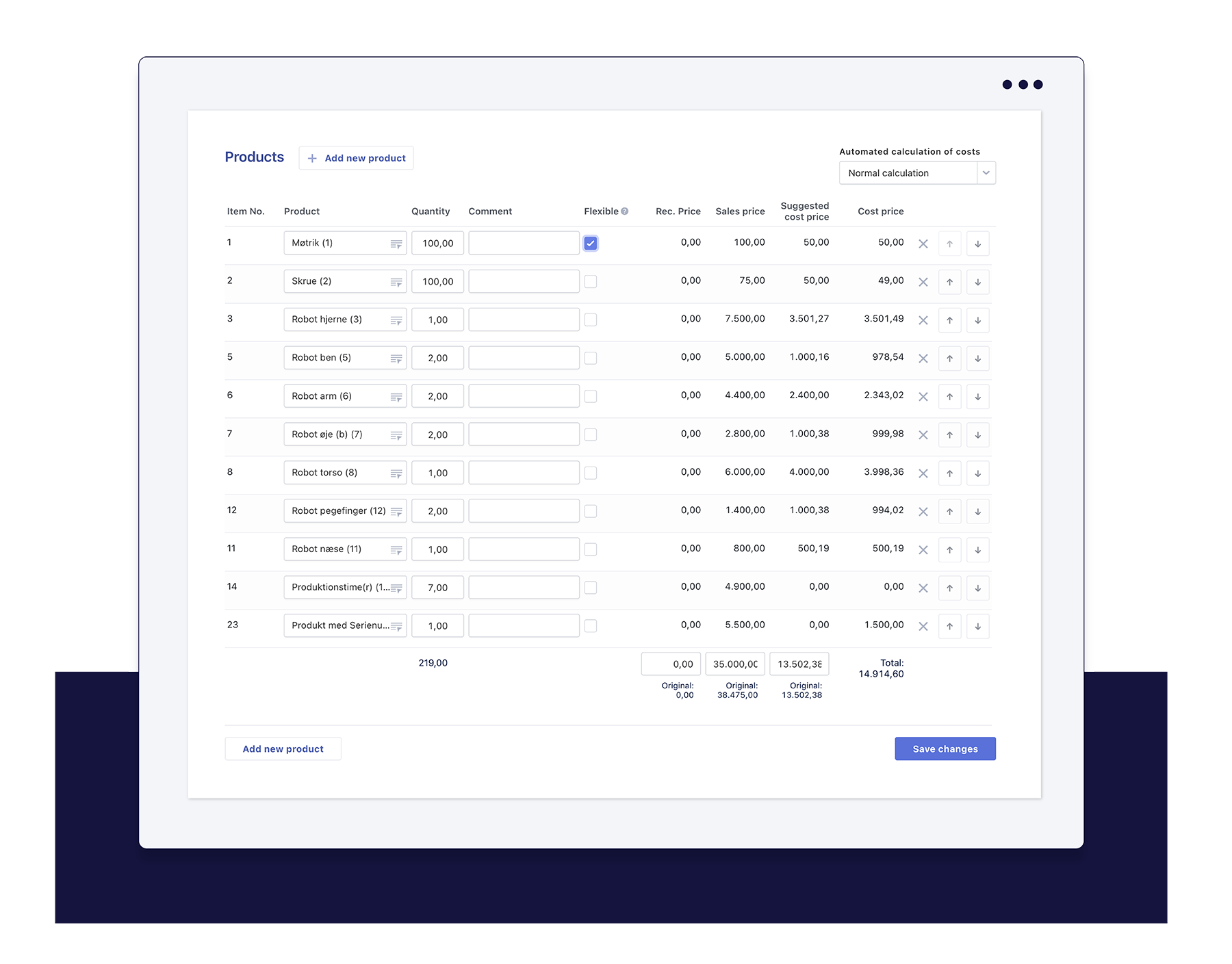

Rackbeat’s digital warehouse system offers you production management that unites all links in your production chain. Our production management includes the ability to create bill of materials, access overviews of your production orders, receive direct updates on the inventory of raw materials, and much more. You can test our production management for free for 14 days without any commitment.