Inventory Management for Manufacturing

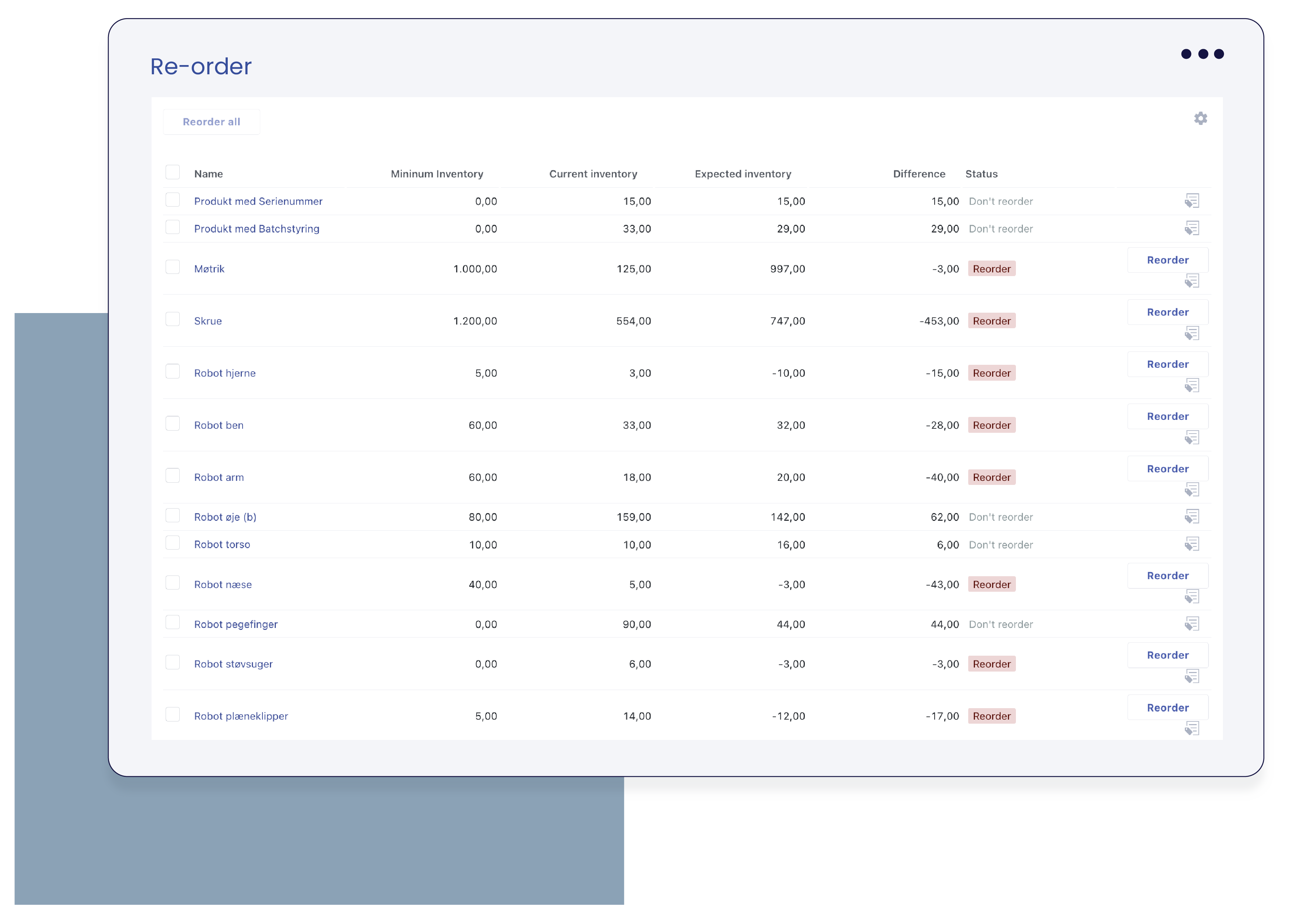

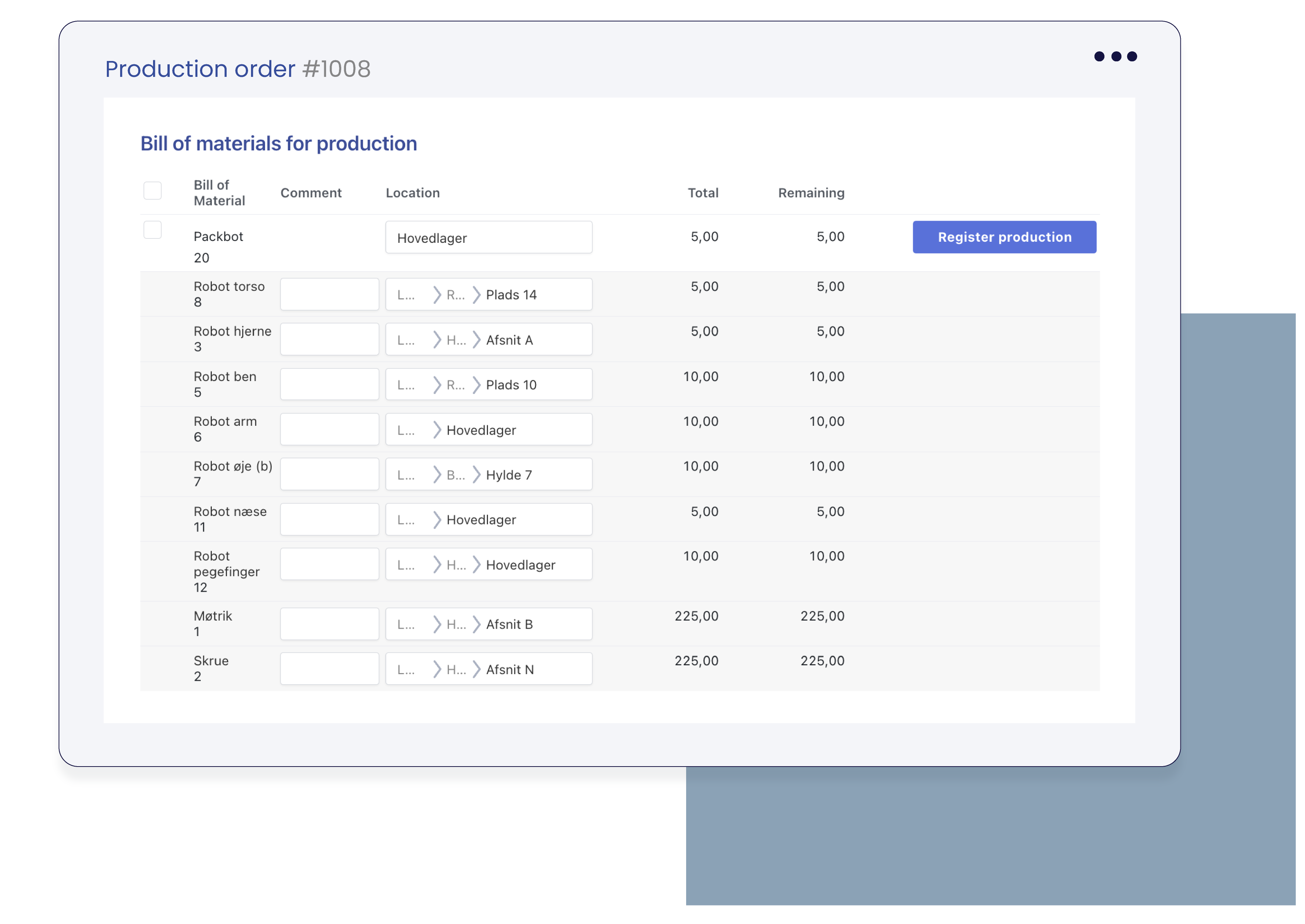

Do you have digital ambitions for your company and lack coordination between the inventory management and manufacturing process? Rackbeat’s inventory management software helps streamline the utilization of your resources, including employees, time and materials, to optimize your production.

Get a solid grasp of all activities influencing the creation of the finished product, including purchasing, receiving, assembling and dispatching your products. Rackbeat streamlines the manufacturing process, ensuring that your production aligns with sales and inventory operations.