Monthly Inventory Turnover Rate

The monthly inventory turnover rate, also known as inventory turnover ratio, is a key metric that measures how many times a company's inventory is sold and replenished over the course of a month. This figure provides insight into the efficiency of inventory management and can indicate how quickly products move through the inventory.

Rackbeat June 21, 2024

Why Calculate the Monthly Inventory Turnover Rate?

The Calculation of Monthly Inventory Turnover Rate

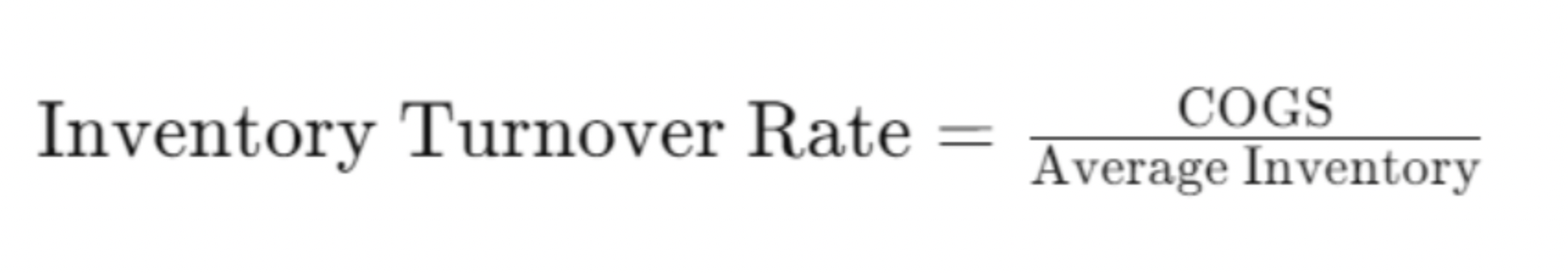

The monthly inventory turnover rate is calculated by dividing the cost of goods sold (COGS) for the month by the average inventory for the same period. The formula is as follows:

This means that the inventory has been sold and replenished four times during the month.

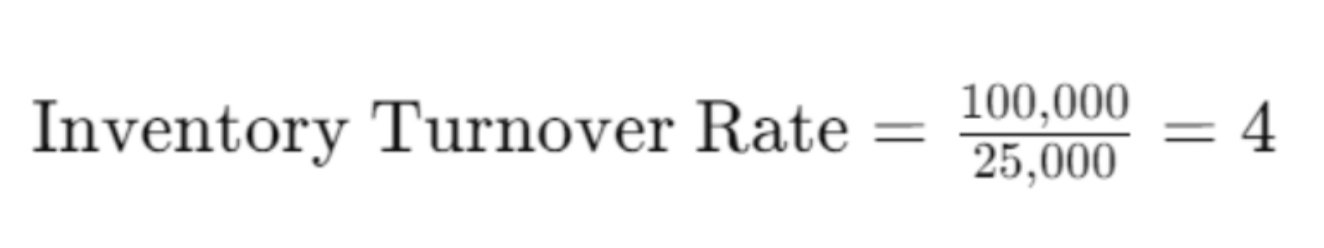

Example: If a company has a COGS of 100,000 DKK and an average inventory of 25,000 DKK over the course of a month, the inventory turnover rate would be:

This means that the inventory has been sold and replenished four times during the month.