Batch Management allows you to actively manage shelf life and proper stock flow.

You gain:

• Overview of batches in stock

• Expiry date management

• Improved stock rotation (e.g. FIFO)

• Reduced risk of obsolete products

• Documented batch history

It is ideal for companies in food, pharmaceuticals, manufacturing, and other industries with traceability requirements.

Register batches upon receipt

When receiving goods, you register the batch number directly in the system.

This means:

• Each product is linked to a specific batch

• You can split quantities across multiple batches

• Inventory is updated accurately per batch

• Traceability is ensured from the first movement

You can always see exactly which batches are in stock.

Select batch at the time of sale

When a product is sold, you select the batch to be delivered.

This gives you:

• Documentation of which batch the customer received

• Full traceability in case of recalls or claims

• Accurate history on both customer and product

• Greater security in your sales process

You always know which batch was shipped – and where it originated.

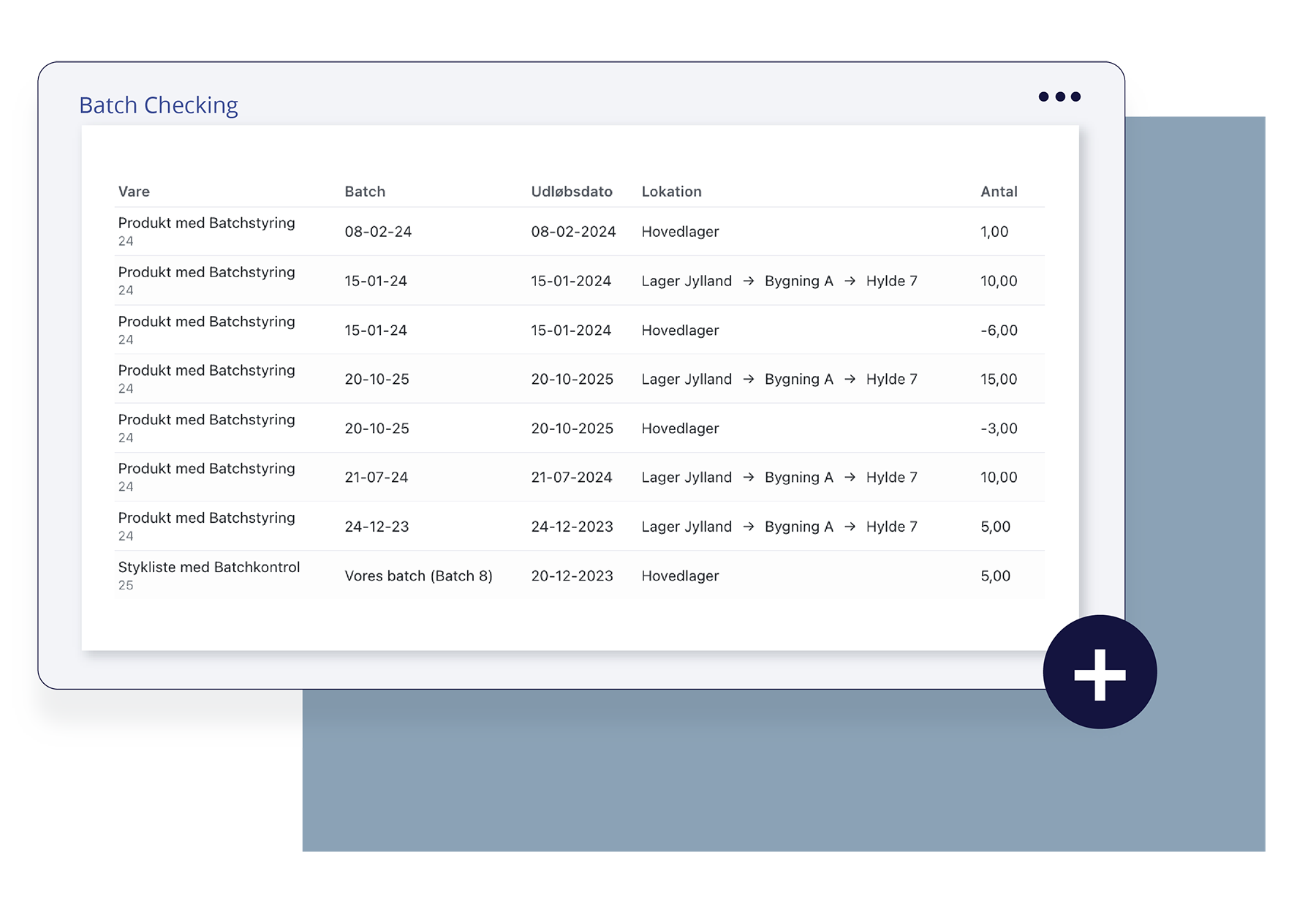

Get complete visibility with batch reports

Batch Management gives you access to detailed reports and overviews directly in the system.

You can:

• View transactions for a specific batch

• See which customers and suppliers are linked to a batch

• Monitor stock levels per batch

• Filter incoming and outgoing movements

This provides a level of documentation that meets both internal requirements and external standards.